APPLICATIONS:

Welding of 9% Cr-1% Mo steels et 9% Cr – 2% Mo ferrei usus pro vi electrica et vasis pressionis altae.

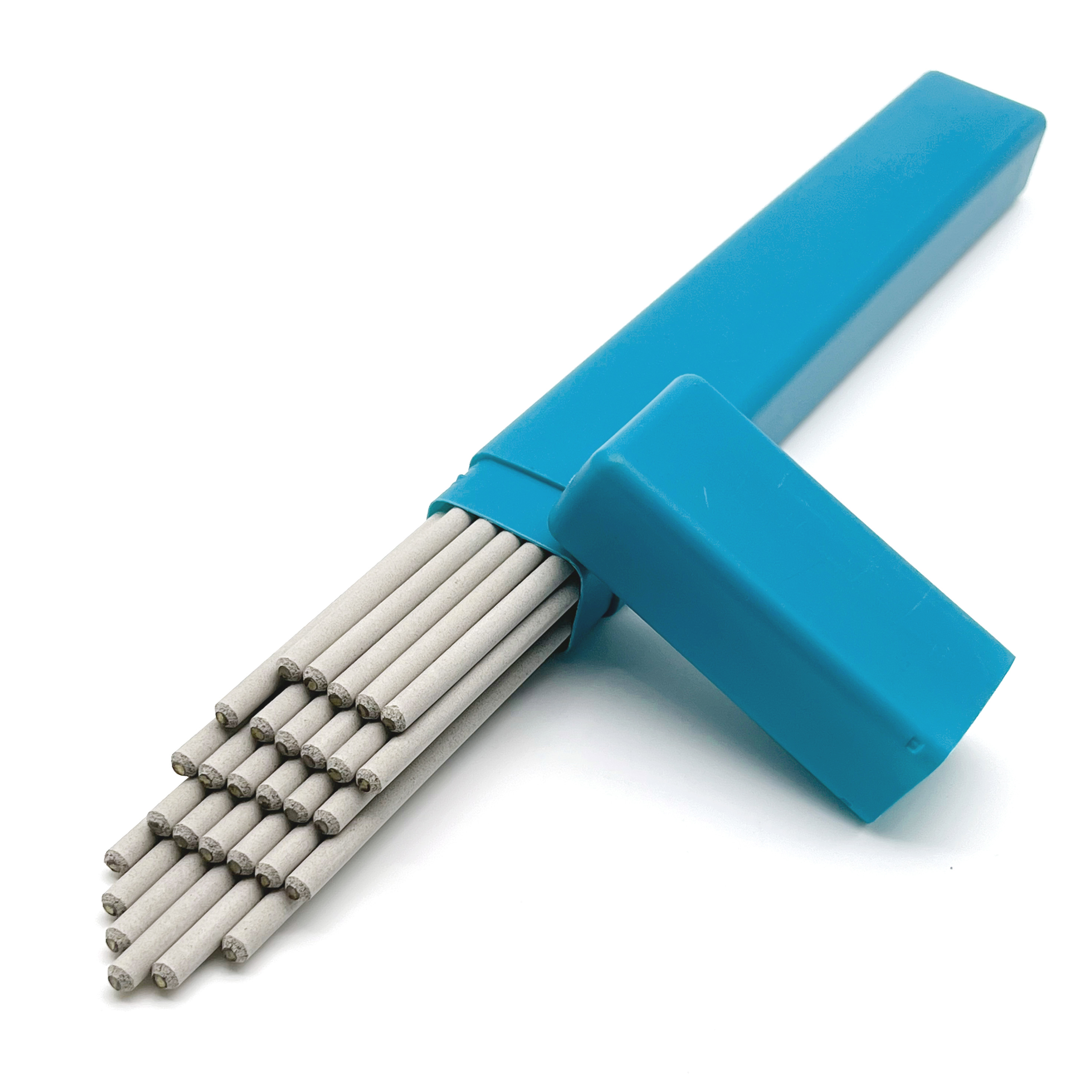

Descriptiones:

PA-8016-B8 hydrogenii humile est electrodum cuius metallum pacneum e 9%Cr-1%Mo constat.Caletas caliditas ferro et ferro ad operas consectetuer calidas destinatur, praesertim in industria petrochemical.Electrode approbari potest propter altitudinem distrahendi fortitudinem, duritiem boni et magni caloris resistentiam.

NOTAE IN USUM:

1. Electrodes sicca ad 350-400°C hora circiter unius ante usum et electrodes reponunt ad 100-150°C post siccationem attente ab humore abstinendi.

2. Methodum gradum retro recipe vel arcum in parva lamina ferrea praeparata ad hunc finem percute ne blowholes ab arcu incipias.

3. Arcum quam brevissime serva.

4. Preheat at 100-150°C.Temperatura applicanda variat secundum crassitudinem laminae et genus ferri conflandi.

5. Attende non excedere proprium caloris input, quia nimius calor-input facit deteriorationem impulsum valorum et vires metalli pugillo cedunt.

IV.TYPICA CHEMICAL COMPOSITIONE CONFERRUMINO ARGENTUM (%):

| C | Si | Mn | Cr | Mo |

| 0.06 | 0.42 | 0.68 | 9.38 | 1.05 |

V. TYPICA MECHANICAE PROPRIETATIS FUNDI METALLIS;

| Distrahens fortitudo N/mm2(Ksi) | Cedant Point N/mm2 (Ksi) | Prolongatio % | PWHT |

| 705 (102). | 560 (81). | 24 | 740° C x 1 hr |

VI.WELDING POSITIONES: OMNES POSITIONS

VII.SIZE RECOMMENDED current range (AC/DC+);

| Diameter (mm) | 2.5 | 3.2 | 4.0 | 5.0 | |

| Longitudo (mm) | 350 | 350 | 400 | 400 | |

| Ampere | Flat | 55 - 85 | 90 - 130 | 130 - 180 | 180 - 240 |

| V & OH | 50 - 80 | 80 - 115 | 110 - 170 | 150 - 200 |